R410A Hybrid VRF - Simultaneous Heating and Cooling

The world’s only Hybrid VRF system

The Hybrid VRF Advantages

1. No critical refrigeration concerns

2. Milder air off temperatures

3. Continuous heating operation

4. Faster defrosts

5. Freeze protection

6. Faster installation

7. No refrigerant noise at indoors

8. Fit out flexibility

9. Connectable to all existing Mitsubishi Electric Controllers

What is Hybrid VRF?

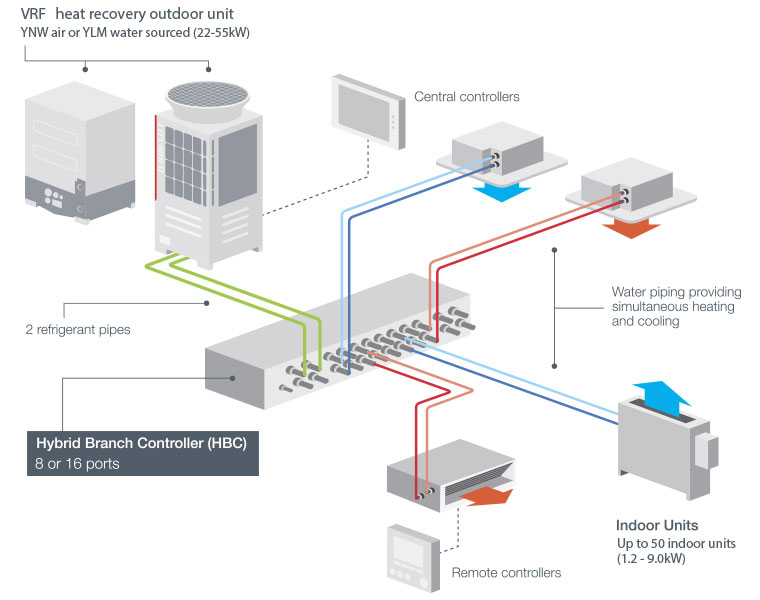

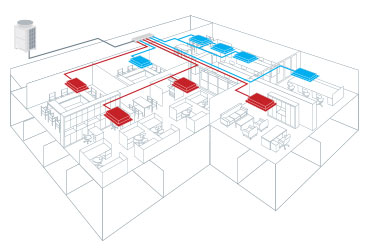

Hybrid VRF is next generation technology from Mitsubishi Electric, the world leader in VRF Solutions. This unique 2-Pipe Heat Recovery VRF System replaces refrigerant with water between the Hybrid Branch Circuit Controller and the indoor units. This revolutionary design minimises the need for expensive and on-going leak detection servicing and is specifically designed for occupied spaces where quiet, energy efficient, simultaneous heating and cooling is valued. Hybrid VRF provides a truly integrated solution for hotels, offices, hospitals and schools where occupant comfort is paramount.Put simply, Hybrid VRF is a 2-Pipe Heat Recovery VRF with water between the Hybrid Branch Circuit (HBC) Controller and indoor units. You can install and design it as VRF whilst enjoying the features of a chiller system. This provides a complete modern solution for office buildings, hotels, medical centres, schools, high-rise buildings, shopping centres and other commercial premises.

Hybrid VRF is quick, easy and flexible to design and install using the same control and network as VRF systems. Furthermore, the decentralised system means phased installation is possible with the same high levels of seasonal efficiency expected with VRF.

With water at the indoor units, Hybrid VRF provides comfortable and stable air temperature control with no refrigerant in occupied spaces, removing the need for leak detection.

Hybrid VRF System Example

NB: Image for representation only

Where Can Hybrid VRF be Applied?

City Multi Hybrid VRF Systems allow for a flexible layout, making installation simple. With the use of Centralised Control, HVRF can be utilised in a wide variety of applications that require individual settings such as hotels, offices, hospitals, nursing homes and schools. Furthermore, HVRF minimises the potential hazards to people, property and the environment that could result from leakages of traditional refrigerant systems in confined occupied spaces.Hotels

Customer comfort is paramount with legislation focusing attention on energy use and seeking to limit the use of refrigerant in occupied spaces. Hybrid VRF minimises the need for leak detection, thereby reducing the total cost of the system and ongoing maintenance of the leak detection system itself.

Offices

Modern offices and commercial buildings need air conditioning systems that provide the highest levels of comfort, freshness and energy efficiency

Hospitals/Medical Centres

With regards to patient health and safety, this system has no refrigerant in the indoor units and can deliver mild off-coil temperatures through the Water-Based Hybrid VRF Indoor Units. HVRF mitigates the need for leak detectors in consulting rooms and provides a solution to critical refrigerant limits outlined in AS/NZS 5149. (1-4) 2016.

Mixed-use Buildings

As we look for ways to balance population growth in crowded city centres, more mixed-use properties are being developed; often combining retail, office, leisure and living spaces in the same building. Hybrid VRF provides a fully adaptable solution benefiting from air or water source options, using an extensive range of controls to ensure optimum performance.

Education

Providing comfort through temperature stability, removal of refrigerant from the occupied space and reduced noise - Hybrid VRF provides a truly integrated solution.

Minimise the Need for Leak Detection

In commercial buildings, additional leak detection systems specific to air conditioning are often installed to safeguard occupants due to increasing safety regulations. This affects hotels in particular, where air conditioners are installed in the room space and occupant safety is critical.Leak Detection System

The leak detection system is designed to trigger an alarm if refrigerant was to leak into the room space and shut down the system to try and prevent harm to the occupants in the room. These systems can be expensive and add to the cost of design, build and maintenance.

Hotel Solution

Hybrid VRF minimises the need for leak detection in each room because there is no refrigerant piped into the room space, just water! This means there is minimal risk of refrigerant escaping into the room space. The Water-Based Fan Coil Units also reduce draughts; improving comfort for guests whilst providing overall savings in ongoing maintenance costs of the equipment for the hotelier.

Throughout a system’s lifetime, annual testing and the recalibration of leak detection sensors adds significant cost to a VRF system. Using Hybrid VRF instead, minimises this need and could provide as much as 30% in maintenance savings over 15 years.

*Based on a real project using costs from a Mitsubishi Electric Business Solutions Partner, UK

Hybrid VRF Key Features & Benefits

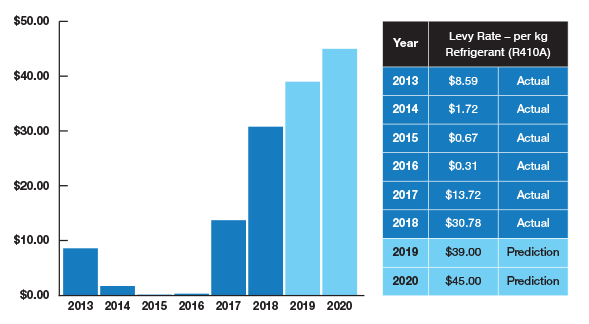

Emissions Trading Scheme

In New Zealand specifically, the ETS (Emissions Trading Scheme) has put a price on greenhouse gas emissions and provides an incentive to reduce emissions and promote strategies to absorb carbon dioxide.

This is known as the SGG (Synthetic Greenhouse Gas) Levy.

Due to the increasing cost of refrigerant associated with the ETS Synthetic Greenhouse Gas Levy (NZ), building capital costs will continue to climb using traditional heating and cooling systems that utilise refrigerants such as R410A.

HVRF reduces this as it uses less refrigerant in the total system.

Energy Saving

- Save more energy by Heat Recovery Operation if heating and cooling operations are required at the same time.

- The more frequently heating and cooling simultaneous operation occurs, the higher the energy saving effect becomes.

- Even higher efficiency operation is now possible by utilising the Centralised Control and scheduled operation.

High Sensible Cooling and Stable Room Temperatures

- Typically offers a 10% increase in sensible cooling vs. traditional VRF.

- Provides superior levels of comfort.

Less Material/Equipment

- Mitsubishi Electric's unique 2-Pipe Heat Recovery System requires less piping than a 4-Pipe Chiller System.

- The system does not require an external pump and control panel that are usually necessary for chillers.

Quiet Operation

- Water-Based Indoor Units: Ducted, Cassette and Concealed Floor Consoles - based on Mitsubishi Electric VRF Indoor Units.

- Low noise levels, variable airflow.

Fully Packaged Solution

- Valves, Pumps and Heat Exchangers are all contained within the HBC.

- Commissioning is simple; pipe sizes are all defined with minor third party items required.

- Uses the same controls and M-NET Network as VRF.

Flexible Application Options

- Air Source YNW (22-56kW) - using the latest City Multi VRF YNW Technology including an aluminium heat exchanger, reduced weight and improved seasonal efficiency.

Simultaneous Heating and Cooling with Full Heat Recovery

- Between fan coils and building zones.

- Optimises flexibility, operability, comfort and efficiency.

Manageable Phased Installation

- Modular, smaller footprint and low weight outdoor units.

- Flexible range of VRF options.

Simplified 2-Pipe Design and Installation

- 2 pipes throughout system - no complex 4-pipe design.

- Flexible design using up to 50 indoor units per system over 4 Hybrid Branch Controllers.

- Copper or plastic pipe on water side.

Heat Recovery Defrost Method

- Typical defrost times of 5 minutes with immediate return to heating.

- Improving comfort throughout the heating season, ideal for office applications.

- No defrost on Water Source VRF Models.

Intuitive Load Adjusting

- The latest YNW VRF refrigerant control plus water side optimisation: flow control valves, inverter driven pumps and heat recovery.

- Providing only the capacity needed, improving efficiency and comfort.

Energy Efficient R410A Refrigerant

- R410A refrigerant allows higher heat transfer than R22.

- The use of R410A in this system has achieved significantly higher COP.

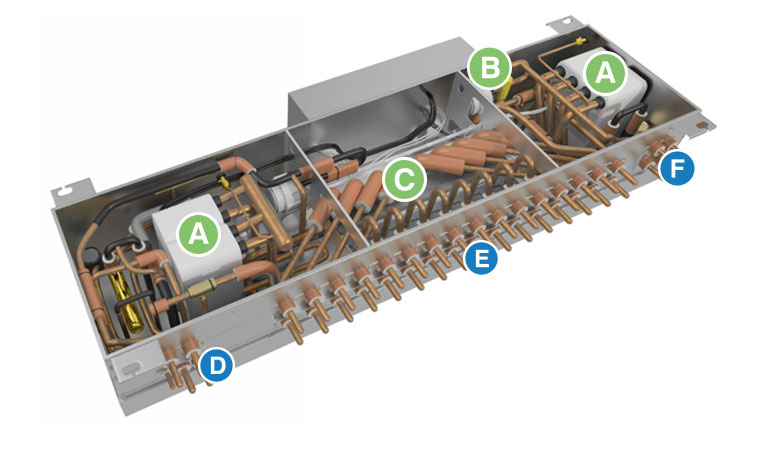

Hybrid Branch Circuit (HBC) Controller

Industry First Patented Technology

NB: Image for representation only

A. Plate Heat Exchangers

This is the point where the refrigerant circuit transfers its energy to the sealed water system. There are two sets of Plate Heat Exchangers, both placed at opposite ends in the HBC. Both sets provide hot water in heating mode or cold water in cooling mode. During mixed mode, one set provides hot water while the other provides cold water to its respective flow header.

B. Pumps

Each set of Plate Heat Exchangers has a water pump. This circulates the closed loop water system between the HBC and indoor units. The discharge flow rate from the pump is controlled by the Valve Block.

C. Valve Block

A Valve Block is connected between each flow and return port of the HBC.

This Valve Block has two features;

- Firstly, it has the choice of selecting between the two flow headers.

- Secondly, it controls the flow of the water sent to the indoor unit, defining the capacity.

D. Refrigerant pipes to outdoor unit

Expansion tank (field supplied) and water filling loop (field supplied)