Manuals

Installation

- R32 Hybrid Pipework Recommendations.pdf - Login required

Service

- R32 Hybrid Service Manual MEE21K013.pdf - Login required

Building owners, facility managers and the construction industry in New Zealand have been looking for HVAC systems that maximises occupant safety, deliver high cost efficiencies whilst minimising the Global Warming Potential of the refrigerants used within these systems.

Mitsubishi Electric’s R32 Hybrid VRF Systems provide a commercially viable alternative solution to traditional R410A systems. It addresses one of the most pressing challenges in the New Zealand air conditioning industry on how to tackle high charge volumes and lower GWP refrigerants in large systems.

Mitsubishi Electric Hybrid VRF changes everything.

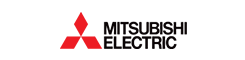

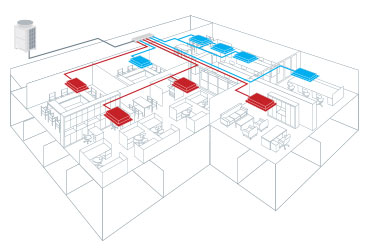

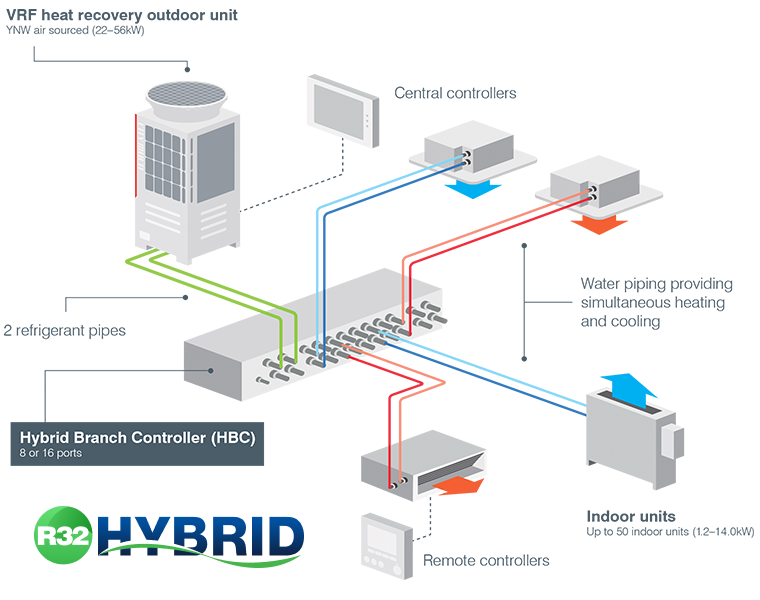

Hybrid VRF is a unique 2-Pipe Heat Recovery VRF System that replaces refrigerant with water between the Hybrid Branch Circuit Controller and the indoor units.

This revolutionary design minimises the need for expensive and on-going leak detection servicing and is specifically designed for occupied spaces where quiet, energy efficient, simultaneous heating and cooling is valued.

Hybrid VRF is quick, easy and flexible to design and install using the same control and network as traditional VRF systems. Furthermore, the decentralised system means phased installation is possible with similar high levels of seasonal efficiency expected with VRF.

With water at the indoor units, Hybrid VRF provides comfortable, stable air temperature control with no refrigerant in occupied spaces, minimising the need for leak detection to comply with AS/NZS 5149. (1-4) 2016.

Hybrid VRF is a truly integrated modern heating and cooling solution for office buildings, hotels, hospitals, medical centres, schools, high-rise buildings, shopping centres and other commercial premises, where occupant comfort is paramount.

Image for representation only.

City Multi Hybrid VRF Systems allow for a flexible layout, making installation simple. With the use of Centralised Control, HVRF can be utilised in a wide variety of applications that require individual space comfort settings such as hotels, offices, hospitals, nursing homes and schools.

Furthermore, HVRF minimises the potential hazards to people, property and the environment that could result from leakages of traditional refrigerant systems in confined occupied spaces.

As we look for ways to balance population growth in crowded city centres, more mixed-use properties are being developed; often combining retail, office, leisure and living spaces in the same building. Hybrid VRF provides a fully adaptable solution benefiting from air or water source options, using an extensive range of controls to ensure optimum performance.

Modern offices and commercial buildings need air conditioning systems that provide the highest levels of comfort, freshness and energy efficiency.

Customer comfort is paramount with legislation focusing attention on energy use and seeking to limit the use of refrigerant in occupied spaces. Hybrid VRF minimises the need for leak detection in the occupied space, thereby reducing the total cost of the system and ongoing maintenance of the leak detection system itself.

With regards to patient health and safety, this system has no refrigerant in the indoor units and can deliver mild off-coil temperatures through the Water-Based Hybrid VRF Indoor Units. HVRF minimises the need for leak detectors in consulting rooms and provides a solution to critical refrigerant limits outlined in AS/NZS 5149. (1-4) 2016.

Providing comfort through temperature stability, removal of refrigerant from the occupied space and reduced noise – Hybrid VRF provides a truly integrated solution. Hybrid VRF delivers comfortable and stable air temperature control with no refrigerant in occupied spaces, minimising the need for leak detection.

Water, rather than traditional refrigerant is at the heart of the indoor units. This means there is minimal risk of refrigerant leaking into small confined spaces. Hybrid VRF minimises the need for leak detection, reducing the total cost of the system and on-going maintenance of the leak detection system itself.

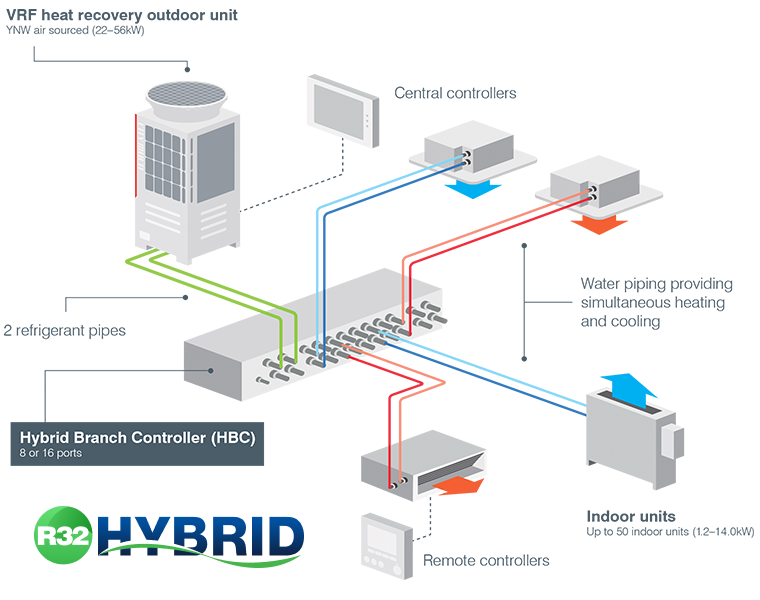

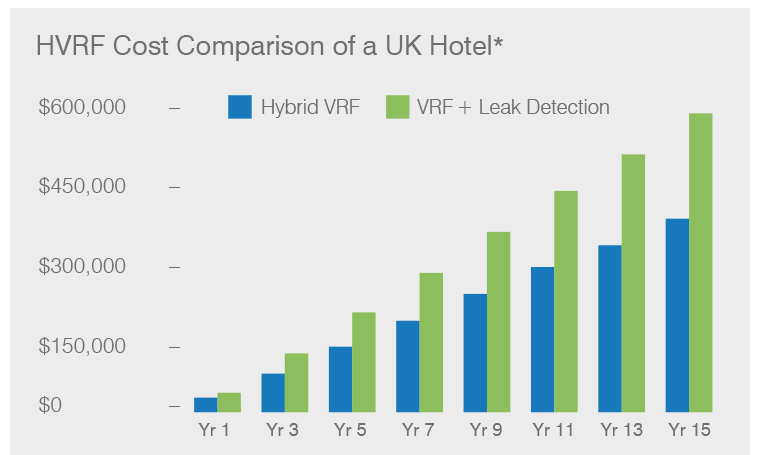

In commercial buildings, additional leak detection systems specific to air conditioning are often installed to safeguard occupants due to increasing safety regulations. This affects hotels in particular, where air conditioners are installed in the room space and occupant safety is critical.

A leak detection system is designed to trigger an alarm if refrigerant was to leak into the room space and shut down the system to try and prevent harm to the occupants. These systems can be expensive and add to the cost of design, build and maintenance.

Throughout a system's lifetime, annual testing and the recalibration of leak detection sensors adds significant cost to a VRF system. Using Hybrid VRF instead, minimises this need and could provide as much as 30% in maintenance savings over 15 years.

* Based on a real project using costs from a Mitsubishi Electric Business Solutions Partner in the United Kingdom.

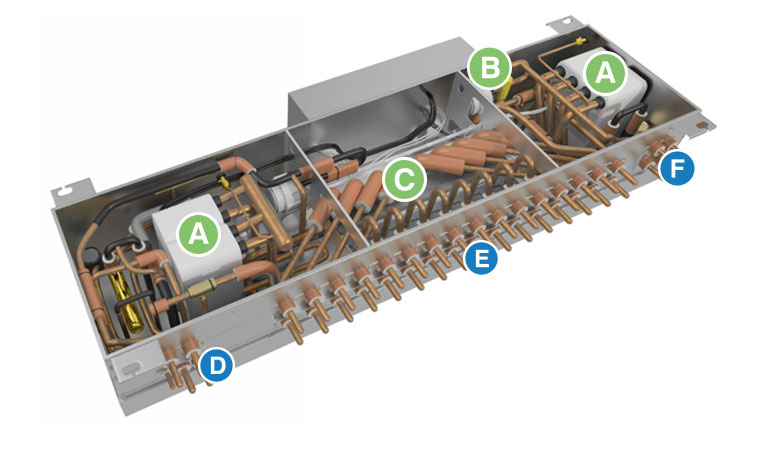

Industry First Patented Technology

NB: Image for representation only

This is the point where the refrigerant circuit transfers its energy to the sealed water system. There are two sets of Plate Heat Exchangers, both placed at opposite ends in the HBC. Both sets provide hot water in heating mode or cold water in cooling mode. During mixed mode, one set provides hot water while the other provides cold water to its respective flow header.

Each set of Plate Heat Exchangers has a water pump. This circulates the closed loop water system between the HBC and indoor units. The discharge flow rate from the pump is controlled by the Valve Block.

A Valve Block is connected between each flow and return port of the HBC. This Valve Block has two features:

Connection to outdoor unit, with expansion tank and water filling loop (both field supplied).

Flow/return to indoor units with 8 or 16 port options available.

Connection point to slave HBC controller.

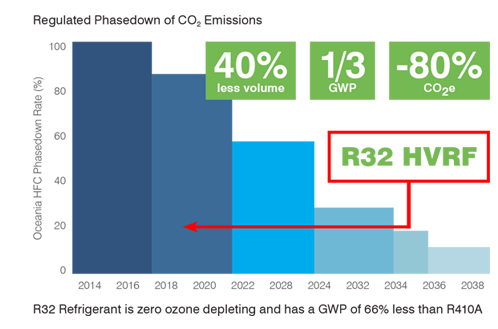

With the environmental pressure on R410A refrigerant increasing, Mitsubishi Electric's commitment to reducing the environmental impact of air conditioning has seen the introduction of New Zealand's first VRF (Variable Refrigerant Flow) solution that has utilised R32 Refrigerant.

Mitsubishi Electric has long been a pioneer in the world of air conditioning and the world's first R32 Hybrid VRF product range puts the company at the forefront of the industry.

The system utilises the low GWP refrigerant R32, providing a real solution that delivers high operational efficiency whilst minimising the global warming potential of the refrigerants used within these systems.

The 2-pipe Hybrid VRF system offer the same comfort levels normally associated with 4-pipe fan coil systems. In addition, the system also features the same design flexibility, operational efficiency and advanced control that Mitsubishi Electric traditional VRF is renowned for.

Because Hybrid VRF now also incorporates R32 refrigerant, it delivers a VRF system with a significantly lower global warming potential (GWP) than existing solutions.

In fact, the shift from R410A to R32 Refrigerant realises a massive 66% reduction in global warming potential.

The global community is in a race to lower its carbon footprint and decrease the rate of global warming before it is too late.

As part of this drive, the Kigali amendment to the Montreal Protocol – ratified on the 3rd of October 2019 – dictates the rate of phase down of HFC refrigerants for New Zealand as part of this strategy – and will commence on the 1st of January 2020.

It is estimated that this directive has the potential to avoid aggregate emissions of more than 90 Giga tonnes CO2e by 2050 – equivalent to two years of total global greenhouse gas emissions (US EPA 2016)!

The key to achieving this goal is the shift away from traditional refrigerants such as R410A.

Replacing traditional refrigerants to those with a much lower GWP, will be a big step towards significantly reducing the future potential rate of rise in the earth's temperature and the catastrophic effects that would have on our planet.

GWP is a measure of the warming potential as compared to CO2 which has a unitary GWP of 1. R32 Refrigerant is zero ozone depleting and has a GWP 66% less than R410A.

R32 refrigerant is being adopted by Mitsubishi Electric as an important step in the process towards the ultimate goal of a zero ODP, zero GWP, efficient, safe, and non-toxic refrigerant.

For example, R410A will hold 2,088 times more heat when released in the upper atmosphere than the equivalent amount of CO2 would.

R32 refrigerant is being adopted by Mitsubishi Electric as an important step in the process towards the ultimate goal of a zero ODP, zero GWP, efficient, safe, and non-toxic refrigerant.

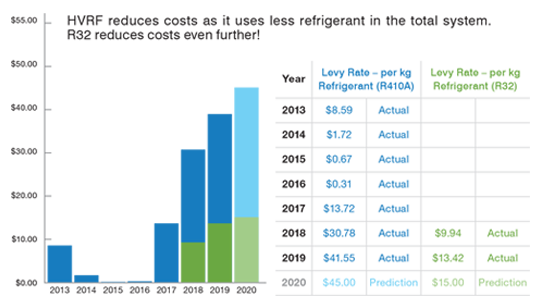

In New Zealand specifically, the ETS has put a price on greenhouse gas emissions and provides an incentive to reduce emissions and promote strategies to absorb carbon dioxide. This is known as the SGG (Synthetic Greenhouse Gas) Levy.

Due to the increasing cost of refrigerant associated with the ETS Synthetic Greenhouse Gas Levy (NZ), building capital and maintenance costs will continue to climb using traditonal heating and cooling systems that utilise higher GWP refrigerants such as R410A.

Throughout a system's lifetime, annual testing and the recalibration of leak detection sensors adds significant cost to a VRF system. Using Hybrid VRF instead, minimises this need and could provide as much as 30% in maintenance savings over 15 years.

In commercial buildings, additional leak detection systems specific to air conditioning are often installed to safeguard occupants due to increasing safety regulations.

The leak detection system is designed to trigger an alarm if refrigerant was to leak into the room space and shut down the system to try and prevent harm to the occupants in the room. These systems can be expensive and add to the cost of design, build and maintenance.

Hybrid VRF minimises the need for leak detection in each room because there is no refrigerant piped into the room space, just water! This means there is minimal risk of refrigerant escaping into the room space. The Water-Based Fan Coil Units also reduce draughts; improving comfort for guests whilst providing overall savings in ongoing maintenance costs of the equipment for the hotelier.

Throughout a system's lifetime, annual testing and the recalibration of leak detection sensors adds significant cost to a VRF system. Using Hybrid VRF instead, minimises this need and could provide as much as 30% in maintenance savings over 15 years.

*Based on a real project using costs from a Mitsubishi Electric Business Solutions Partner, UK

R32 Hybrid VRF is an advanced simultaneous heating and cooling system with heat recovery and delivers a proven alternative solution to traditional R410A VRF systems.

Save more energy by Heat Recovery Operation if heating and cooling operations are required at the same time. The more frequently heating and cooling simultaneous operation occurs, the higher the energy saving effect becomes. Even higher efficiency operation is possible by utilising the Centralised Control and scheduled operation.

The system is based on a 2 Pipe Heat Recovery VRF System but uses water as a heat exchange medium between the Hybrid Branch Controller and the indoor units.

As such, the system combines the comfort of a traditional hydronic system with the efficiency and ease of modern VRF air conditioning – giving you the best of both worlds.

The small footprint and modular design means building owners can now take advantage of a manageable phased installation.

Legislation is now demanding that leak detection equipment is installed alongside VRF air conditioning when it is used in small occupied spaces in accordance with AS/NZS 5149. (1-4) 2016.

The Hybrid VRF architecture minimises the need for leak detection in these confined areas. This is because water instead of refrigerant is piped between the branch box and the indoor units mounted in each room. As a result there is no risk of refrigerant escaping into the room space.

In addition to maximising occupant safety, significant up front equipment and on-going maintenance cost savings are able to be realised because expensive leak detection systems are not required to be installed and maintained within occupied rooms.

Mitsubishi Electric's unique 2-Pipe Heat Recovery System requires less piping than a 4-Pipe Chiller System. The system does not require an external pump, valves, sensors, actuators, or other ancilliary controls associated with conventional 4-Pipe Chiller Systems.

Because water instead of refrigerant is circulated through the terminal fan coils, quiet operation and silent off cycle operation is assured.

Occupant comfort is paramount. Hybrid VRF Systems deliver milder off coil temperatures and are specifically designed to provide a gradual rate of change of temperature within the air conditioned space delivering a comfortable and stable environment.

Furthermore Hybrid VRF offers on average a 10% increase in sensible cooling at terminal compared to traditional VRF systems.

The rapid and continuing price rises of R410A refrigerant is placing a strain on the viability of traditional VRF systems.

As a result Mitsubishi Electric have developed R32 Hybrid VRF to ensure that both customers and installers not only have an alternative, but also get the added benefits of lower refrigerant costs, efficient performance and advanced controls.

Existing VRF units use R410A which has a GWP of 2,088, the newly adopted R32 refrigerant has a reduced GWP of 675 – that's 66% less than R410A.