Mitsubishi Electric Quality

Quality you can rely on

- All units line tested

- Performance tested

- 800 hour heat stress test

- 2000 hour endurance test

Your Guarantee of Excellence

This emblem is your assurance of the very best in technology and quality as it represents Mitsubishi Electric’s continuing efforts in making our heat pumps the industry standard. Every Mitsubishi Electric Heat Pump is a product of painstaking research, relentless testing, and a resolute determination to improve upon vital performance characteristics. As a result, our heat pumps have become more durable, less costly to operate, quieter, easier to install and maintain, and better able to distribute air evenly throughout any type of interior. This kind of commitment to quality enables our products to create remarkably pleasant environments that will ultimately make your life more comfortable.

The brand Mitsubishi Electric is not to be confused with the brand Mitsubishi Heavy Industries. Both brands may share the 3 red diamonds but are manufactured in completely different factories to completely different specifications.

Indoor Unit

Designed for Fast, Simple Installation

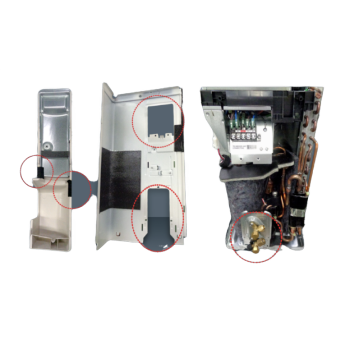

Gravity Lock Installation Plate

The indoor unit installation plate features three fixing points. In addition to left and right fixings, a centre fixture is placed slightly lower. This ensures that, if the left or right fixing points break or fail, the centre point will prevent the unit from falling.

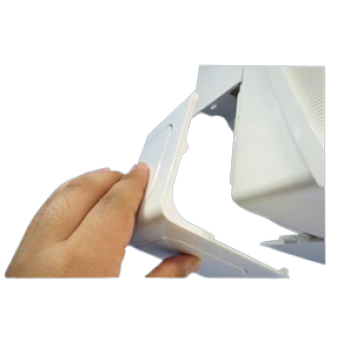

Front Panel

The front panel is easily detachable and includes Side Holders on both sides of the panel for easier opening.

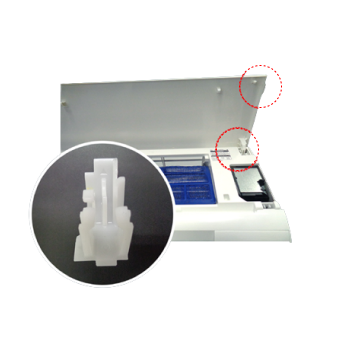

Pre-Cut Corner Box

The indoor unit features a detachable corner box piece on both sides of the indoor unit, allowing easy adjustment of the drain hose for either left or right piping. The pre-cut design allows for easy removal of the part.

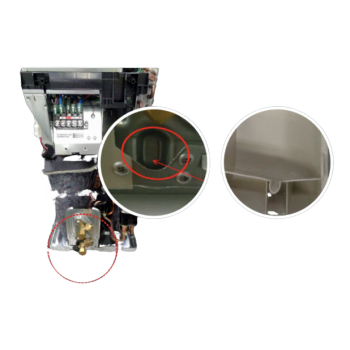

Simple Drain Hose Attachment

The drain hose can be easily fixed in place using a special built-in clip which ensures a tight connection and minimises the risk of a leak occurring.

Designed for Convenience

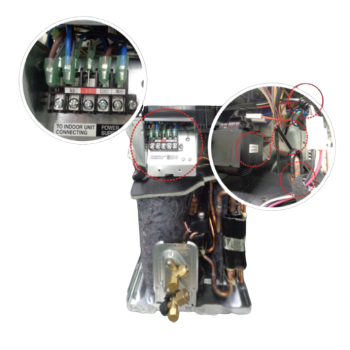

Electronic wiring is enclosed in a special metal housing box in the indoor unit, which can be accessed easily without removing the front panel, simplifying PCB service and maintenance.

The metal housing box features quick reference instructions for wiring preparation prior to connection.

Designed for Superior Quality

Silent Operation

Using a uniquely designed nozzle developed by Mitsubishi Electric, noise generated by air movement is significantly reduced.

Condensation Prevention

As condensation can occur in specific operating conditions such as cooling in a high humidity environment, Mitsubishi Electric has introduced insulation and an aluminium sheet around the air outlet to prevent moisture forming.

Fire Protection Design

Circuit boards are contained within a metal housing box, protecting the electronic circuitry from dust which can create a fire hazard in the event of a short circuit.

Easy-clean Structure

Maintenance of the heat exchanger, fan, and air outlet is easy, with the indoor designed to allow easy removal of the parts for cleaning or washing of dirt and mold which cause odor and reduced performance. Easy-clean helps optimise airflow and more efficient performance.

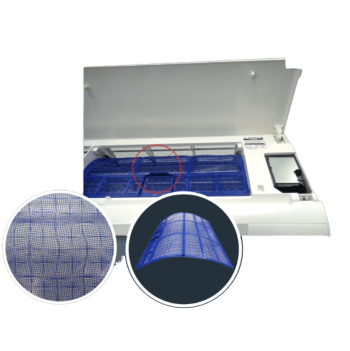

3D Filter Design

Mitsubishi Electric filters are equipped with a honeycomb (3D) design which helps to enlarge the filter capture area and improves dust collection performance when compared to conventional flat-type filters. The filters are easy to remove for maintenance.

Designed for Fast, Simple Maintenance

Removable Nozzle

The air outlet nozzle is detachable from the body of the indoor unit and can be easily removed during servicing by simply disconnecting the connecting cable.

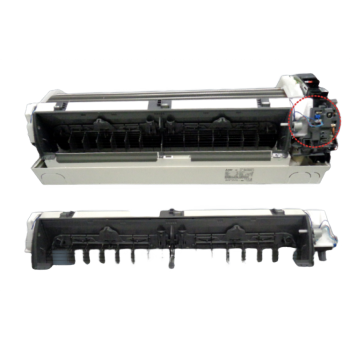

Easy Access Circuit Board: The metal housing that contains the electronic circuitry is easy to open, allowing technicians to simply open the box to access the PCB component without having to remove the box.

Easy Access Circuit Board

The metal housing which contains the electronic circuitry is easy to open, allowing technicians to simply open the box to access the PCB component without having to remove the box.

Outdoor Unit

Designed for Fast, Simple Installation

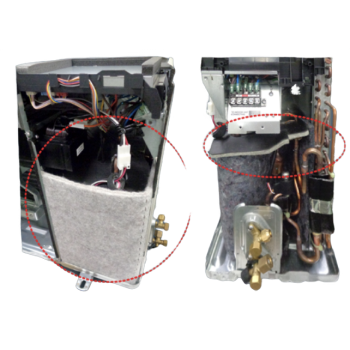

Re-configured Connection Ports

- Specifically designed to allow adequate spacing between ports

- Allows for easier piping work

Designed for Fast, Simple Installation

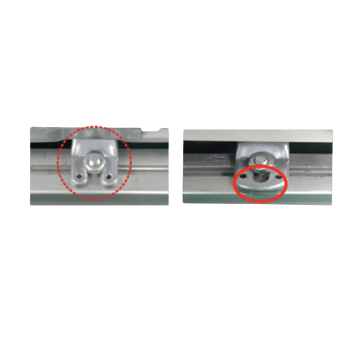

Adjustable Bolt Fixture

Each bolt hole is designed to allow for efficient and straightforward installation, offering flexibility in positioning and ensuring stability from vibration.

Designed for Superior Quality

Rust Prevention

Mitsubishi Electric uses galvanised steel in the base of the outdoor unit to minimise the risk of rust occurring.

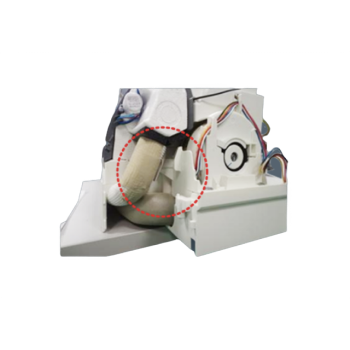

Silent Operation

Designed with quietness in mind, Mitsubishi Electric outdoor units are fitted with a felt cover at the top and sound-proof material in the base to reduce sound from the compressor.

Durable Components

The thickness of the metal top panel has been increased, which helps reduce potential damage during transportation or installation. Mitsubishi Electric panel thickness is approximately 60% higher than other brands.

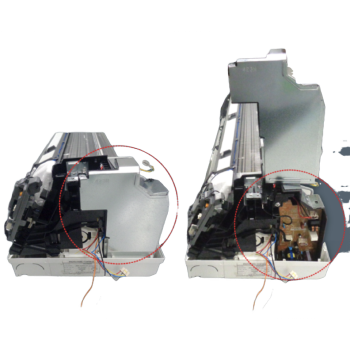

Anti-vibration Structure

Internal copper pipes are equipped with dampers to prevent any failures occurring, such as cracks, dents, or leakages as a result of vibration during transportation or operation.

Water Resistant Design

Mitsubishi Electric outdoor units are designed to prevent water and moisture ingress by ensuring all gaps between the panel and electrical circuit board areas are insulated or sealed.

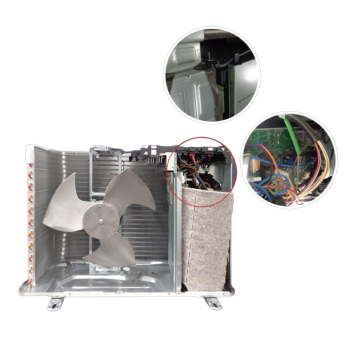

Fire Protection

Wiring and coils are fitted with rubber tubes and insulation to prevent electrical short circuits and fire risks where the wiring and copper pipes are close to each other.

Central Drainage Structure

Unlike some other manufacturers, Mitsubishi Electric covers ports with a service panel which is equipped with a pan to catch dew drops from the port and transfer it to the outdoor unit base where it is discharged through the drain hole.

Fire Protection

Mitsubishi Electric utilises special non-flammable material in the service panel to minimise risk in the event of a fire event outdoors. In addition, the service panel is equipped with a metal cover housing the electrical wiring connection point to ensure any short circuit is contained.

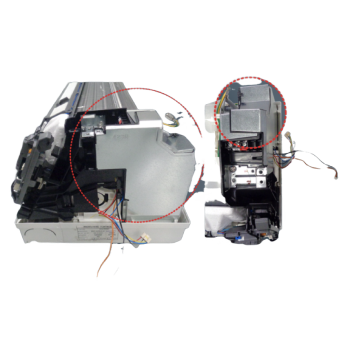

Fire Protection

To prevent the risk of short circuit caused by insect or rodent ingress, the PCB component is positioned out of the way and covered by metal housing. Silicon coating is also applied to the back of each PCB for additional protection.