What Makes CITY MULTI Technology Superior

Mitsubishi Electric's industry leading City Multi VRF technology is designed for today's building needs. With emphasis placed on energy efficiency, adaptability, reliability and control, City Multi addresses the most current market issues. Utilising integrated air conditioning, hot water, ventilation and control solutions City Multi is the benchmark in VRF technology.

Inverter Driven Technology

Striving to continually meet increasing demands of our customers, Mitsubishi Electric was the first in the industry to offer inverter-driven systems. Using inverter technology, systems produce precise output, matching exact requirements of any building. Working efficiently to ensure no valuable energy is wasted by over-heating or over-cooling; greatly reducing running costs.

Increased COP Performance

COP or "Coefficient of Performance" is a measure of the useful energy a system can deliver compared to the energy it consumes. It is calculated by dividing the energy output by the energy input of a system. The higher the figure, the more efficient the system is deemed to be. Mitsubishi Electric VRF models, the world's highest energy-efficient air conditioners, will undoubtedly reduce millions of tons of CO2 emissions.

Not only does Mitsubishi Electric provide some of the most efficient R2 series, simultaneous heating and cooling systems on the market, they have developed a high COP range of condensers as well. The PURY-EP range of condensers (available in nineteen sizes) has a full load COP of 5.29 in cooling and 5.47 in heating.

If your client is after the highest efficiency possible for their project, then look no further than the Mitsubishi Electric high COP, EP series of air conditioning.

Intelligent Power Module (IPM) Technology

Mitsubishi Electric's YNW-A range provides precise control of energy input, through its Intelligent Power Module (IPM) technology. Using this technology it is possible to closely match the building requirements, achieving more accurate control of the occupied space. Using incremental 1Hz steps of capacity control, the amount of power input required is significantly reduced, resulting in greatly improved COP's.

IPM technology ensures effective performance under partial load conditions, a condition that most systems will be in for the majority of their normal working life. By taking account of the efficiency at both part load and peak load conditions, R410A City Multi is designed to provide unbeatable year-round efficiency.

Heat Interchange Circuit

The unique Heat Interchange Circuit (HIC) enhances efficiency by providing additional sub-cooling. This allows the expansion device to effectively control the refrigerant distribution. This increases the operating efficiency and reduces the volume of refrigerant in each system.

More Efficient Refrigerant

Governments in many countries are enforcing a ban of HCFC-based refrigerants for new installations. The most popular choice for chillers, R22, an HCFC-based refrigerant, has been targeted by the Montreal Protocol to be phased out in new equipment. Because of these restrictions, R410A (a blend of HFCs, which do not deplete the ozone) refrigerants are desirable.

R410A is a more efficient refrigerant as it has a higher specific heat capacity when compared to R407C or R22. This higher energy carrying capacity allows for smaller pipe sizes, longer pipe runs and reduces the volume of refrigerant within a system. This is a major factor for safety and environmental requirements in the design, manufacture, installation, operation, maintenance and disposal of refrigerating systems.

Water-Cooled - Unique to Mitsubishi Electric

Combining the features of VRF and a water circuit using CITY MULTI WR2/WY, heat is rejected to a water source rather than to the outside air. The advantage of water cooled systems is that the water can be delivered at optimised temperatures and volumes, which allows even greater flexibility and increased COP.

WR2 (Heat Recovery)

Mitsubishi Electric now offers double heat recovery operation. The first heat recovery is within the refrigerant system, where simultaneous cooling and heating operation is available with heat recovery performed between indoor units.

The second is within the water loop, where heat recovery is performed between the PQRY units. This double heat recovery operation substantially improves energy efficiency and makes the system the ideal solution for modern office buildings, where areas require cooling even in winter.

Benefits of Two Pipe VRF

Mitsubishi Electric City Multi VRF (variable refrigerant flow) is the cutting edge in commercial air-conditioning technology – the only two-pipe simultaneous heating and cooling system in the world. Proven in the field under rigorous conditions, two-pipe technology is not only cheaper to install, but is durable, reliable, energy efficient and provides superior levels of control accuracy.

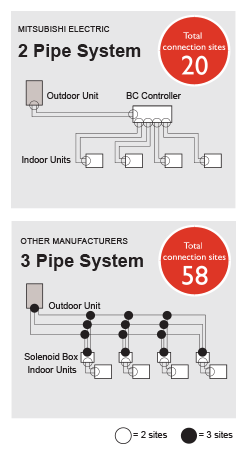

1. Less Pipe Connections

On a City Multi R2 Series VRF with four indoor units system, there are 20 refrigerant joints, compared to an equivalent three-pipe system with 58 connections. Each extra joint requires extra labour, materials and time. Copper prices have risen significantly and less copper pipe means much less capital cost for equivalent projects. This makes City Multi R2 a significantly cheaper product to install. There are also no expensive proprietary branch fittings required. Fewer pipe connection sites also mean less potential leak sites.

2. Tight Dead Band Control

Two-pipe architecture allows for quick, individual changeover of indoor units from heating to cooling. Due to the unique engineering of the BC (branch control) box, +/- 1°C of set point is possible with +/- 1.5°C dictating changeover mode.

3. Flexibility for Future Alterations

Two-pipe architecture makes future proofing and servicing of the VRF system simpler, reducing through-life costing. Alterations and additions to individual branches are made easy by installing branch ball valves at the time of installation. This allows individual branches to be worked on while the rest of the system is still in service. All BC connections are brazed, reducing further possible leakage sites. Future additions to the system can be engineered and added while the system is still in operation.

4. No-Oil Recovery Cycle

Unlike three-pipe systems, R2 systems do not require regular oil recovery cycles. With less refrigerant volumes and velocities during mode change over, oil recovery is minimized. This prevents zone-temperature drift during recovery cycles and improves energy efficiency and control accuracy.

5. Heat Recovery in the BC Box

Heat recovery between indoor units is carried out in the BC boxes. This allows pinch technology (heat integration) energy recovery to be diverted, reducing pipe transmission losses. Heat is redirected in the valve blocks, directly to the branch that requires it, reducing overall running costs and lifting operational COP's.

6. Less Electrical Connection Sites

Two-pipe VRF has significantly less electrical termination points than equivalent three-pipe systems. This reduces complexity of the initial wiring process and simplifies fault finding; reducing installation cost, time and materials. Fewer components in the system mean less plant to potentially fail in the future.

How do City Multi Systems Work With Only 2 pipes?

The secret of City Multi Heat Recovery Systems lies in the BC Controller. The BC Controller houses a liquid/gas separator, allowing the outdoor unit to deliver a mixture (2 phase) of hot gas for heating and liquid for cooling, all through the same pipe. Three-pipe systems allocate a pipe to each of these phases. When this mixture arrives at the BC Controller, it is separated and the correct phase delivered to each indoor unit depending on the individual requirement of either heating or cooling.