New Zealand’s First Zero Carbon Hospital Features Efficient e-Series Modular Chillers

Temperature control in hospitals and medical facilities is incredibly important, so when looking at air-cooled chillers to service these areas, reliability is paramount to ensure patient wellbeing.

But with a 2019 report by global organisations Arup and Health Care Without Harm finding healthcare to be responsible for 4.4% of the world’s global net emissions, hospitals must now also look towards increasing their operations energy efficiencies.

The Goal

AMT Maintenance Services with the aid of Powell Fenwick Consultants was tasked with supplying and installing a suitable air-cooled chiller option that could replace the ~400kW 2-circuit unit in the existing space on the plant deck. The purpose of the chiller is to provide cooling to operating theatres, recovery and ancillary clinical spaces as well as comfort cooling to the wards, offices and reception year-round. With temperature control essential to hospital services and patient comfort at all times, having a chiller system that is reliable, with easy maintenance and high redundancy was key.

The Challenge

Being a retrofit project, AMT Maintenance Services needed a solution that would work in the current plant space on the building's rooftop. Furthermore, as the pre-existing 2-circuit chiller could not function during maintenance, nor handle the whole building if one of the circuits failed or went into defrost, the contractor needed to find a solution that could provide much higher redundancy.

As the chiller was the only source of cooling for the hospital, the installation had to be tightly managed over a short Christmas shutdown period, in order to minimise the possibility of disruption to the private hospitals critical services in the new year.

The Solution – Modular Chiller Technology

Three 180kW e-Series Modular Reversible Heat Pumps were chosen due to the flexible, easy to install modular format and to provide a total system capacity of 540kW that offered much higher capacity and redundancy. The e-Series system includes four refrigeration circuits per module so if a unit needs maintenance or a failure occurs, the two remaining module's circuits continue to provide capacity to the building. The new e-Series Modular Chiller system could fit the three e-Series units in the existing space of the one unitary chiller.

A substantial factor the client and installer considered alongside requirements when evaluating options, was the availability of local technical support, options for extended warranties for peace of mind and ongoing additional health check services. As a result, the client signed up to the Black Diamond Technologies Extended Warranty program, which includes quarterly health checks and ongoing system monitoring over and above the routine maintenance contract.

e-Series Chillers Prove Ideal for Retrofits

Connection of the new e-Series Chiller to the pre-existing systems was relatively simple for AMT Maintenance Services, completing an upgrade of the primary chilled water circulating pumps to accommodate the difference in duty and flow requirements as well as pipework to suit the new modular layout and connection points.

The new units were then interfaced with an onsite energy management and set point BMS system as well as additional monitoring via a Mitsubishi Electric Service Tool.

Built-in Headers Simplify Design, Installation

and Maintenance

While the e-Series is available with and without internal headers, the built-in header N-type was selected to ensure individual modules could be isolated from the water circuit thanks to the inbuilt isolation valves. This allows for maintenance to be carried out while the other modules remain in operation.

The inbuilt headers also reduced pipework, which not only saved space but installation time on the roof. As a result, a quicker changeover of the failing chiller could be achieved.

Equipped with High-Efficiency

Inverter Compressors

The multiple advanced DC inverter-driven scroll compressors incorporated within each module allows for an operating capacity range of 8% to 100% for each module. The energy efficient operation aligns with the hospital's sustainability goals to maximise overall efficiencies.

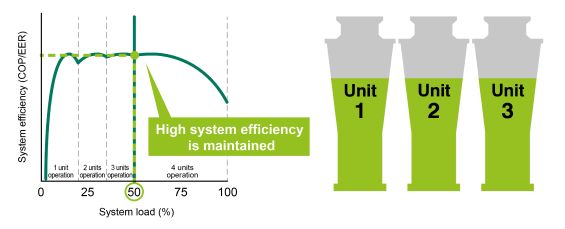

Features Optimum Frequency Control to Maintain High Part Load Efficiency

The Mitsubishi Electric e-Series Chiller / Heat Pump Range is designed to optimise chiller compressor frequency based on the number of connected units, maintaining the highest part load efficiency possible. This control can be implemented by simply using the unique M-NET control, without the need for any other on-site design.

With three units operating in one bank, this function improves system efficiency when operating at low to medium loads. Furthermore, the run time of each unit is equalised by the control system, this prevents uneven wear on the units and extends the lifespan of the system.

BS Treatment Further Protects the Outdoor Units from the Coastal Environment

While the standard e-Series models come with excellent corrosion resistance, the Coastal Protection BS models goes a step further by treating external panels and other key elements to a higher degree, providing further protection from aggressive salt environments. Mitsubishi Electric's BS Treatment was applied to the chassis, panel work and airside coil to ensure longer life when compared to standard finish products in harsher sea air environments.

Installation Successfully Completed in a

Short Timeframe

As the hospital was still running on the original chiller right up until the changeover, all the enabling works for the mounting of the new units had to be carried out around the existing equipment. New plinths were fabricated around the existing chiller and a custom designed steel plant deck was designed, templated and fabricated offsite to suit the new configuration.

This came together perfectly on the day of the crane lift and the new plant deck dropped seamlessly onto the footings - the three e-Series modules were all able to be landed onto their exact fixing points on the new plant deck. The onsite works were carried out during the Christmas holiday period towards the end of 2020 and was handed over to the client fully commissioned and operational ready for the building to re-open at the start of the new year.

e-Series Chillers and Heat Pumps are Readily Available in New Zealand

Black Diamond Technologies holds stock of the Mitsubishi Electric

e-Series Chillers and Heat Pumps. As such, they were able to be delivered quickly to meet the project's sharp deadline.

The Results

Forté Health now operates with piece of mind that cooling will always be provided to key areas such as operating theatres, recovery and ancillary clinical spaces, offices and reception while using technology that helps maximise efficiencies to align with their sustainability goals and continue to be a leader in the health care sector.

Published: Tuesday, 24 May 2022