R410A 150kW & 180kW Modular Chiller / Heat Pump

The 150kW and 180kW e-Series modular chillers allow for up to six individual units to be connected together to provide a system capacity up to 1,080kW. Available as a cooling only or heat pump version, the e-Series is suitable for both comfort and process cooling applications.

Models

E-Series | 150kW Series EAHV-P1500YBL-(N)-(BS) Heat Pump Model

EACV-P1500YBL-(N)-(BS) Cooling Only Model

E-Series | 180kW Series

EAHV-P1800YBL-(N)-(BS) Heat Pump Model

EACV-P1800YBL-(N)-(BS) Cooling Only Model

P1500

Nominal capacity

150.0 kW per module

Up to 6 modules at 900kW

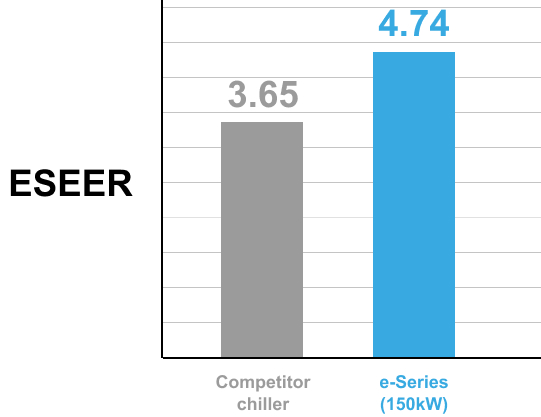

ESEER = 4.74

COP = 3.29

EER = 3.19

Cooling Water Temp 5.0°C to 30.0°C

Heating Water Temp 30.0°C to 55.0°C

*Nominal rating capacity is in accordance with EN14511

P1800

Nominal capacity

180.0 kW per module

Up to 6 modules at 1080kW

ESEER = 4.45

COP = 3.15

EER = 2.90

Cooling Water Temp 5.0°C to 30.0°C

Heating Water Temp 30.0°C to 55.0°C

Features

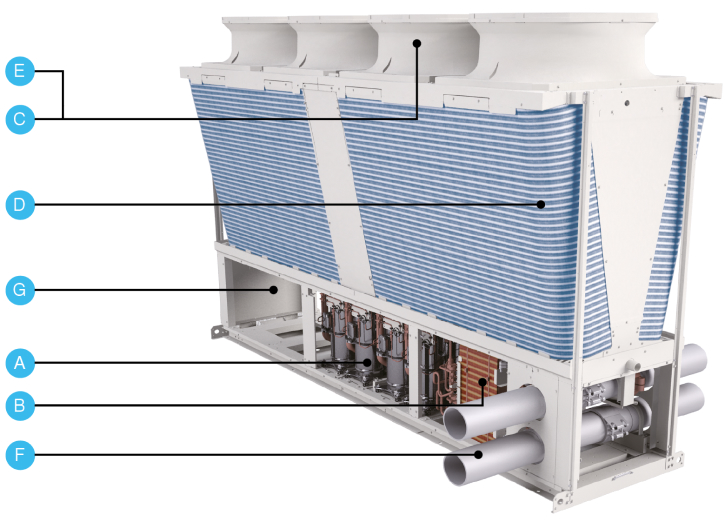

A: High efficiency inverter compressors

The multiple advanced DC inverter-driven scroll compressors incorporated within each module allows for an operating capacity range of 8% to 100% for each module.

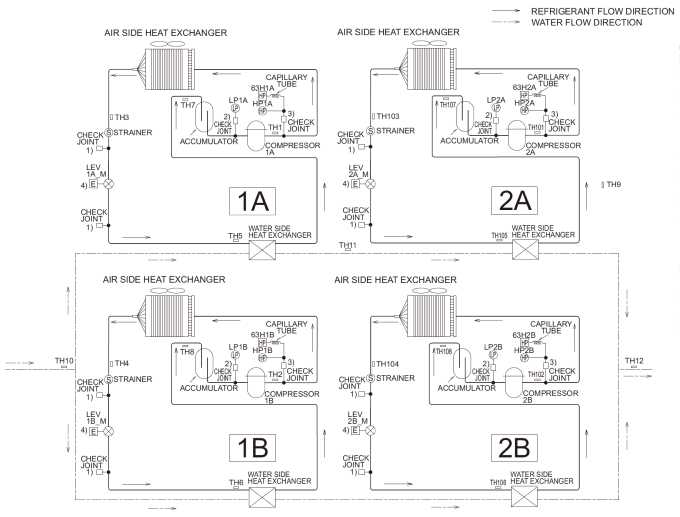

B: Four independent cooling circuits

Each compressor has its own refrigeration circuit and shares a twinned plate heat exchanger all located within the module. By modulating the evaporating temperature individually, overall system efficiency can increase by an additional 3.9%, compared to single evaporating refrigeration cycles.

C: Fan inverter control

Each refrigerant circuit has separately controlled, inverter-driven DC fans, allowing for more precise control to save energy and optimise system efficiency.

D: Y-shaped high performance compact air heat exchangers

The use of high performance, compact heat exchangers allows for a greater surface area whilst also keeping the units much narrower than conventional chillers.

The e-Series heat exchangers are equipped with a premium bluefin coating, offering a high level of protection against corrosion.

E: Fans

The fan blades have improved airflow characteristics and a newly designed trailing edge that suppresses air turbulence to increase efficiency and reduce noise levels.

F: Optional Internal header pipe

The internal header pipes simplify design, installation and maintenance and makes the e-series range modular and suitable for almost any situation.

G: Digital indicator

A dedicated digital indicator inside the PCB displays high pressure, low pressure, water inlet temperature, water outlet temperature, error codes etc., thereby aiding service and maintenance.

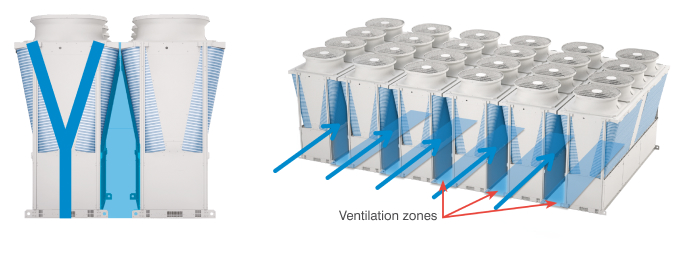

Unique Y-shaped structure

When multiple modules are connected together, the shape of the structure allows for efficient airflow across all air sourced coils.

Four Independent Refrigerant Circuits

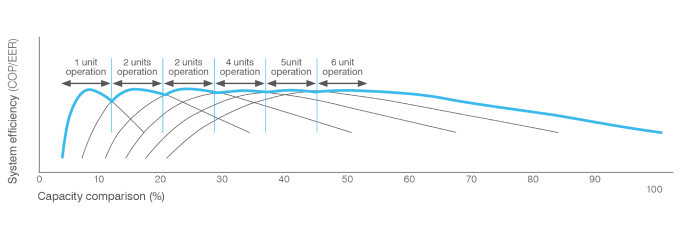

Optimum frequency control for further energy saving

When multiple modules are connected, the frequency of each inverter compressor is controlled during operation to increase the overall module efficiency. This control can be implemented by simply using the unique M-NET control, without the need for any other on-site design.

* The following is an example of operation.

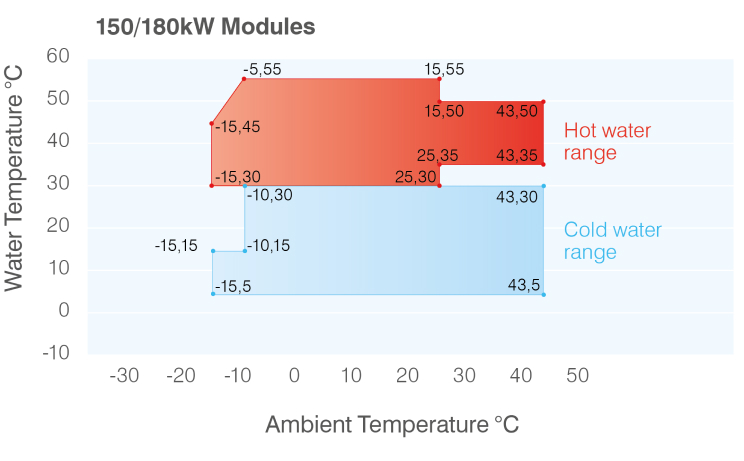

Wide Operating Range

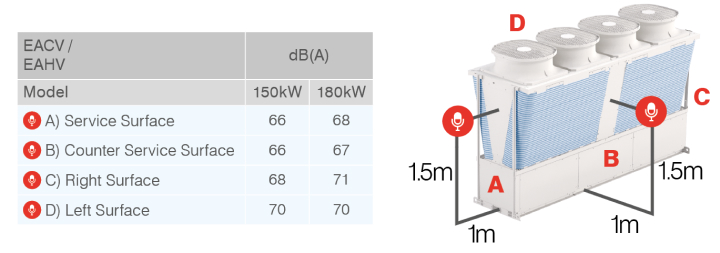

Low Noise Levels

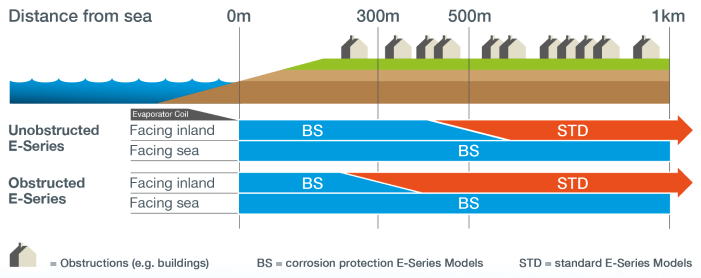

e-Series Coastal Protection Models

While the standard e-Series models come with excellent corrosion resistance, the Coastal Protection e-Series models go a step further by treating external panels and other key elements to a higher paint specification, providing further protection from aggressive salt environments.

High Annualised Efficiency = Lower Running Costs