CAHV Series

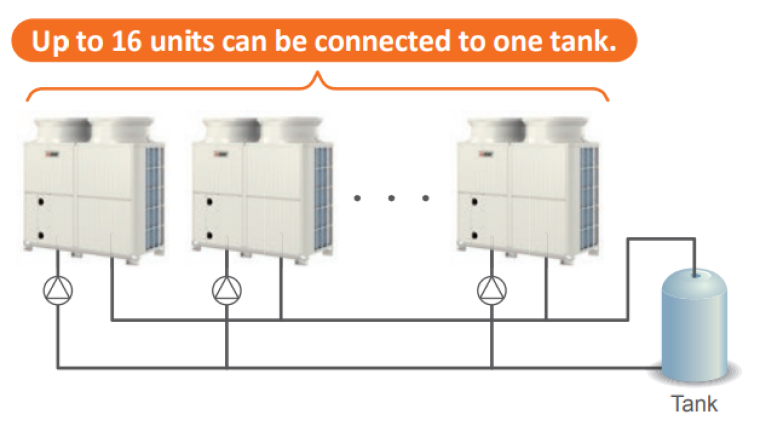

Mitsubishi Electric’s CAHV commercial series hot water heat pump can be the backbone of your commercial hot water production. Each CAHV packaged hot water heat pump can provide up to 40kW of water heating and up to 16 units can be grouped together for a total capacity of 640kW. Its unique R454C compatible inverter compressor technology ensures superior performance even in the harshest of conditions. The high water flow rate of CAHV makes it ideal for large comfort heating or commercial process applications, and it is capable of up to 70°C water outlet temperatures. All with the superior reliability and quietness associated with any Mitsubishi Electric machine.

Models

CAHV-R450YA-HPB(-BS)

-20°C ambient temperature

Note: Above capacity ratings are all nominal rated.

Features

Low-GWP Refrigerant R454C

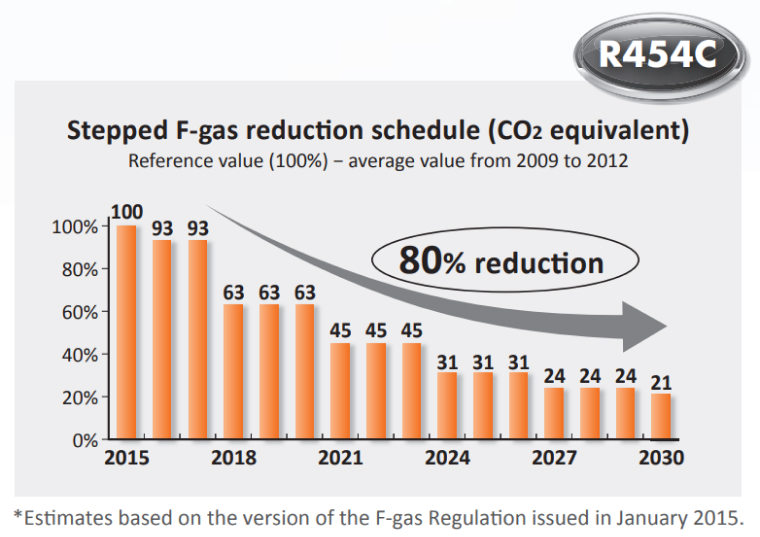

In Europe, the F-gas Regulation is implemented to prevent global warming and unwanted climate changes. The current target is to reduce the total amount of F-gases (CO2 equivalent) by about 80% across Europe by 2030 compared to 2015. Mitsubishi Electric offers more environmentally friendly hot water heat pumps that use the low Global Warming Potential (GWP) refrigerant R454C.

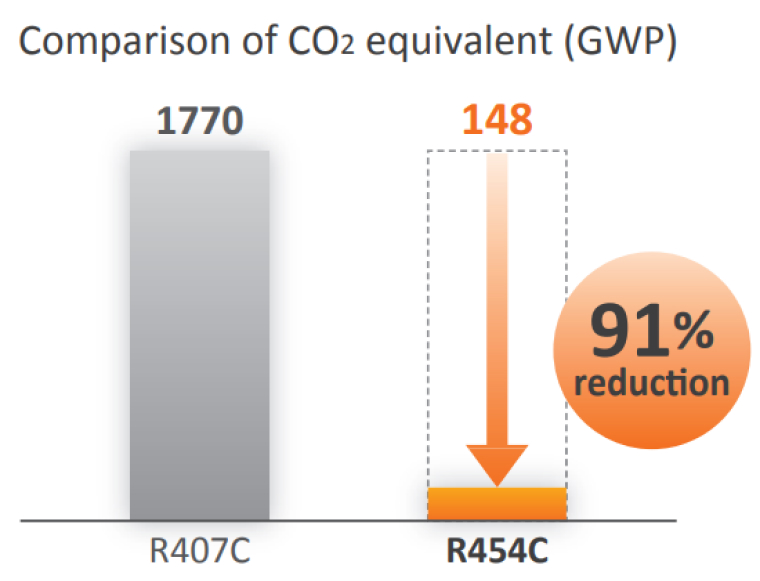

The GWP of R454C refrigerant is 148. It is approximately 91% lower than the R407C refrigerant which is used in the conventional model (CAHV-P500YB-HPB)*.

*Source: IPCC 4th assessment report.

Low Running Costs and Wide Operating Temperature Range

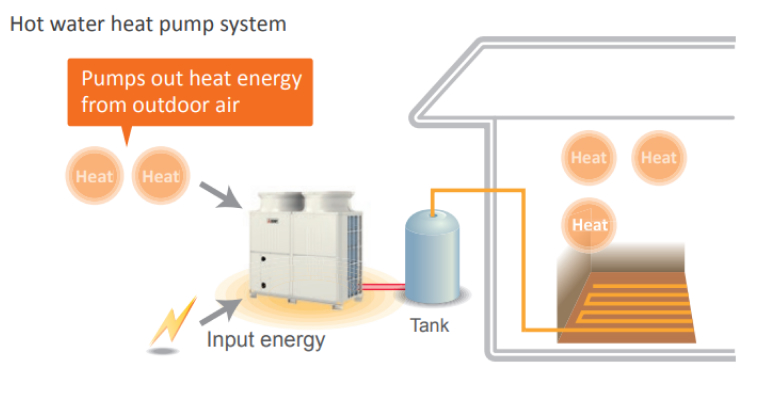

Hot water heat pumps absorb energy from the surrounding outdoor air and transfer it into refrigerant. Heat energy absorbed from air heats up the incoming water via the heat exchanger. The Seasonal Coefficient of Performance (SCOP) of the new CAHV is 3.57 (low temperature conditions) / 3.24 (medium temperature conditions)*, which means it can extract more than three times the input electric energy.

* Above values are based on Regulation (EU) No.811/2013.

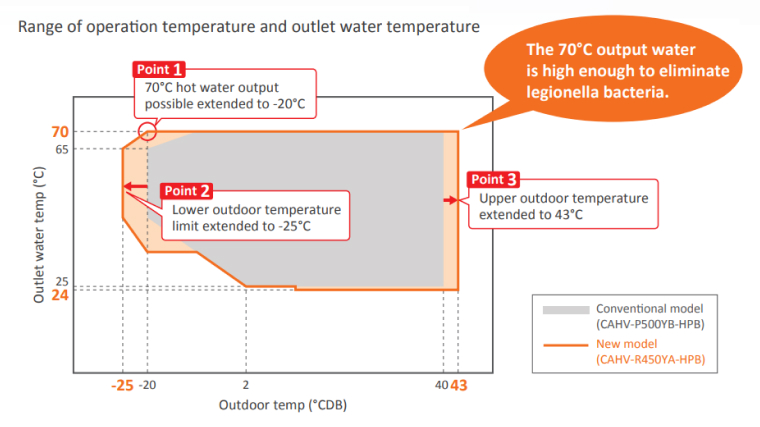

The lower outdoor temperature limit for 70°C hot water output has been extended from -10°C in the conventional model to -20°C in the new model. The operating temperature range has also been improved from "-20°C to 40°C" to "-25°C to 43°C". It is suitable for heating and heat-retention operations.

Low Maintenance and Design Flexibility

Clean and Safe

The hot water heat pump system runs on electricity only. It does not require the safety measures and periodic inspections required for gas and other combustion appliance-mounted systems, and does not generate toxic substance such as NOx.

Rotation Function

When two or more units are in the system, the unit runs alternately, ensuring an optimum product lifecycle for both component units.

Multi-Unit Installation

The number of outdoor units can be adjusted from 1 to 16 according to the tank storage capacity.

Wide Variety of External Input / Output

Various system configurations are available.

- Two external output for backup heater

- Analog input to control capacity

- Defrost signal

* Refer to the Data Book for other functions.

Key Technologies

Refrigerant Circulation and Pressure Control with Two LEVs

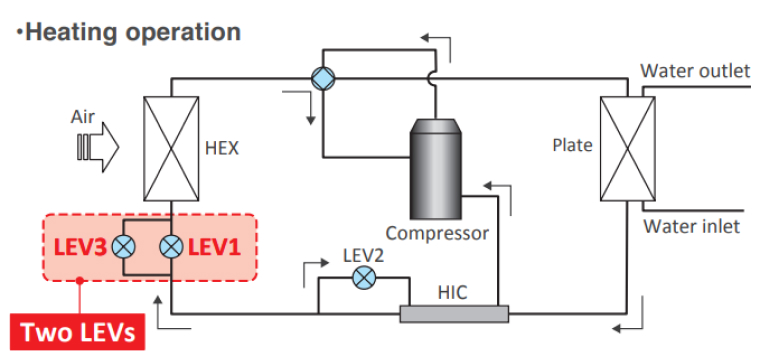

The R454C refrigerant is a lower pressure refrigerant than R407C, which is used in the conventional model, and R410A, which is commonly used in air conditioners. Because low-pressure refrigerants have a low refrigerant density, securing circulation volume can be challenging especially when the refrigerant circuit pressure drops due to low outdoor temperatures or other conditions.

Linear expansion valves (LEVs) before heat exchanger (HEX) were increased from one to two and placed in parallel. The opening of LEV1, which focuses on securing the refrigerant circulation volume, and LEV3, which focuses on controlling the refrigerant pressure, are controlled respectively to control the refrigerant circulation.

New compressor has been developed

New Spiral Structure

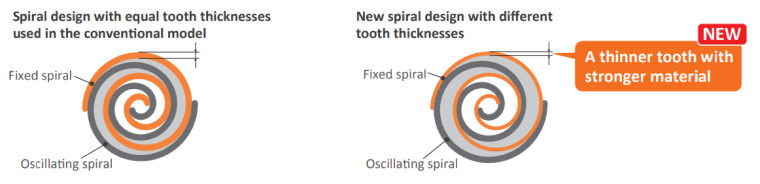

The low density of R454C refrigerant requires an increased amount of refrigerant to be discharged from the discharge section. The new compressor uses a new material for the fixed spiral section, which enables the tooth to be thinner while maintaining their strength. The height of the teeth has also been lengthened. This synergistic effect has resulted in a 15% increase in the extrusion volume from the discharge section compared to the conventional model (assuming the scroll section of the old and new compressors has the same volume).

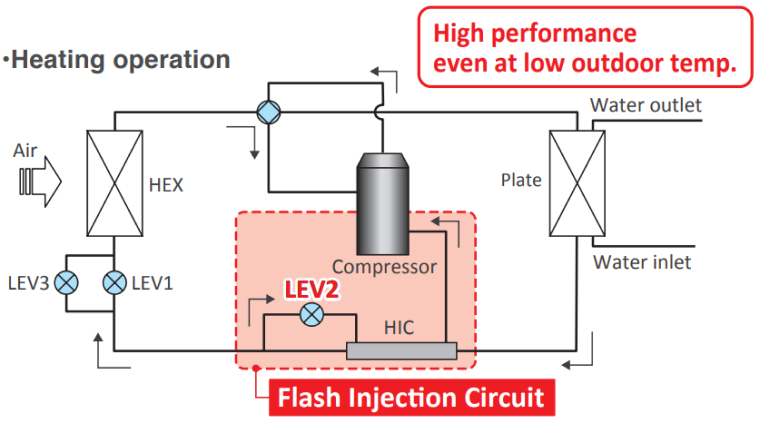

Flash injection circuit

The flash injection circuit is a Mitsubishi Electric technology used in air conditioner for cold climates. The CAHV also adopts this circuit to help units produce high-temperature water even at low outdoor temperatures.

Liquid refrigerant, whose pressure is reduced by the LEV2, exchanges heat in the HIC circuit and becomes gas-liquid two-phase refrigerant. This two-phase refrigerant flows into the injection port in the compressor for controlling the increase of the discharge temperature. Therefore the optimal amount of refrigerant can be provided to the system via the compressor.

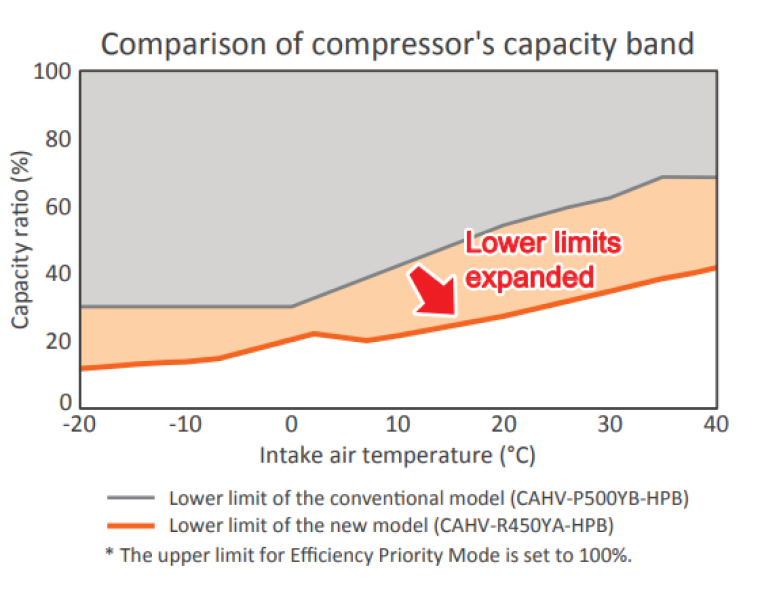

Expanded Inverter Frequency Control Lower Limit

The new compressor has an expanded lower limit of the frequency control range compared to the conventional model. This expanded lower-limit control helps minimize thermo ON/OFF frequency during low-load operations, such as in intermediate seasons, and improves energy efficiency.